At McHenry Pressure Cleaning Systems, we know the toll that salt corrosion can take on machinery. That’s why we offer a full range of cleaning products to stop this mineral in its tracks. Our equipment protects metal substances from further corrosion.

What is Corrosion?

Corrosion is defined as wearing away and breakdown of solid materials, according to the Oxford Dictionary. While moisture is the most important factor for corrosion, temperature also plays a role. In fact, the corrosion rate can more than double for every 10 degrees it rises in temperature. It’s in salty marine environments where corrosion rates dramatically increase.

It’s important to understand the causes of corrosion, the physical and financial damage it causes, and how to prevent it.

Why is it a Problem?

Corrosion can cause metals to become less structurally safe leading to continuous maintenance or worse, accidents or collapses. It can cover an entire surface to a small, specific area, so it’s important to realize how your environment can affect your metal belongings and be aware of how to treat corrosion.

In its raw and dry form, salt (NaCl) has a neutral pH between 6-8. However, when it’s used to melt ice and snow, it mixes with moisture; this powerful combination of salt and water accelerates the corrosion process.

When road crews apply salt, the goal is to improve highway safety. That’s because salt reduces the freezing or melting point of water. Applying salt to roads is critical for public safety.

Though salt-treated roads are less slick and much safer for driving, the salt causes havoc on vehicles. The chemical concoction of oxygen and impurities releases ions on metallic surfaces; this chemical reaction results in a powerful recipe for salt corrosion.

How to Prevent Corrosion

By knowing the type of metal you’re trying to protect, you can find the correct coating that will prevent corrosion.

Beginning in the 1990s, some municipalities began treating winter roads with brine, a solution of salt in water. Brine treatment has become ever more popular over the years.

Brine is sprayed on as a liquid; its telltale sign is leaving lines on the highway. It sticks to and penetrates smaller spaces much more effectively than salt solutions. Brine is also safer for other drivers and is a much more economical solution than road salt. Also, because it’s a liquid, it won’t bounce up and hit your car.

However, brine (magnesium chloride) is much more corrosive than rock salt. In fact, above 20 degrees, magnesium chloride can form acid and cause corrosion of metals.

“Brine is highly effective but can cause serious damage to vehicles if it’s not immediately addressed,” said Bob Baboian, a fellow with the National Association of Corrosion Engineers.

Just as it more effectively penetrates road spaces, brine also coats and clings to the surfaces of your car or truck, both outside and in the undercarriage.

Braving the Storm

You made it through an ice storm and are relieved to be pulling into your driveway or bay, but the salt or brine on your vehicle is just getting to work. In fact, the rusting process has already begun. If the salt mixture remains on your vehicle, it creates irreparable damage.

Corrosion can eat away at the frame of your vehicle, as well as in other places that are harder to see. Water and salt are kicked up in the underbelly of your car, where they sit and corrode. The DMV says the following areas are most at risk:

- Exhaust system

- Muffler

- Coil springs

- Subframe

- Hydraulic brake system

If you park in a garage–or another protected space away from the elements–much of the salt will drip and drain off your vehicle. But be warned, steel can immediately begin to microscopically corrode after exposure to winter elements.

What’s the Price of Rust?

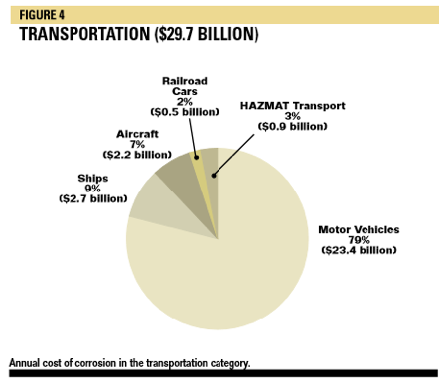

Though the numbers are outdated, they still tell a powerful story. In 2002, the U.S. Federal Highway Administration (FHWA) released a study called Corrosion Costs and Preventive Strategies in the United States. Per their research, the direct cost of metallic corrosion was $276 billion each year. Broken down by category, we see that motor vehicles alone suffered damage to the amount of $23.4 billion which is significant.

Of that more than $23 billion price tag, according to the study: “$14.46 billion (was) attributed to corrosion-related depreciation of vehicles. Another $6.45 billion is spent on repairs and maintenance made necessary by corrosion, and $2.56 billion represents increased manufacturing costs from corrosion engineering and the use of corrosion-resistant materials.” Some have estimated this equates to $400-$500 spent on corrosion for every ton of salt spread.

Bust That Rust

You can take steps to prevent corrosive damage to your vehicle. At McHenry Pressure Cleaning, we recommend the following six steps for corrosion prevention:

- Keep your car or fleet of vehicles painted. Unpainted metal and aluminum are the most vulnerable to corrosion. Even if you have small sections of rust, make sure to sand them down and apply touch-up paint.

- Wax before winter. Apply a nice coat of wax all over your car before cold weather arrives. This protective layer will help stave off damage caused by salt and brine.

- Baby your older car. After eight years, the National Highway Traffic Safety Administration (NHTSA) says older cars are especially prone to corrosion.

- Pretreat your undercarriage. Check with your local mechanic or collision center. Many offer an oil pre-treatment solution. They can spray this on your car’s exposed parts to create a coating, helping to prevent road salt or brine from sticking to metal parts underneath your car.

- Deflect, when possible. Purchase fabrication shields and deflectors to protect components and prevent salt from being sprayed directly on specific areas.

- Get a pre-winter inspection. A trained eye can more quickly assess potential trouble areas and treat them before road crews begin spreading corrosive ice.

Winter Hacks

If freezing temperatures have already arrived, you can still play offense. Here are five ways you can minimize damage and help maintain your vehicle.

- Stay on the straight and narrow. Avoid potholes and puddles whenever possible. You don’t want to splash snowy salty debris underneath your car.

- Lead, don’t follow. If you’re driving directly behind the ice truck, you’re going to take the brunt of the salt application. Change lanes and move around the de-icing machines.

- Scrub away debris. As soon as possible after an ice or snowstorm, make sure you clean off the salt from your car. Pressure wash all surfaces as thoroughly as possible. Use one of our high-quality alkaline detergents during your wash process. If you need to clean an entire fleet, talk with us about custom wash bays.

- Use an under spray. Don’t forget about your undercarriage. Use a drive-through car wash or select a hand wand where you can access under your car. At McHenry, we sell special undercarriage cleaners that connect to your pressure washer.

- Finish with a salt neutralizer. This provides additional protection for your vehicle.

McHenry has Solutions

The experienced professionals at McHenry Pressure Cleaning Systems are here to help you with all your cleaning needs to prevent salt corrosion. We offer free delivery on equipment and soaps/detergents. In addition, we provide training to show you how to properly and safely operate your equipment.

Trust our representatives to help you select the right type of:

- Soaps and detergents: You’ll also appreciate our Aqua Shine Wash & Wax.

- Pressure washer: We’ll discuss the pros and cons of hot vs. cold, electric vs. gasoline, and small vs. large units, among many other considerations.

- Parts and accessories: From machine parts that keep your pressure washer operating to unique accessories that will make your cleaning easier, McHenry stocks everything you could possibly need to banish salt and brine.

- Wash systems: If you own a fleet of trucks, McHenry can custom design drive-through or self-service cleaning systems. We can even recycle the collected water.

Whether you wish to rent or buy equipment, McHenry Pressure Cleaning has the cleaning solutions that will help you prevent salt corrosion. Contact one of our experienced representatives today. We look forward to becoming your trusted source for high-quality pressure cleaning and environmental equipment and systems.